What is a Scissor Lift?

These makers go by a variety of names, the most typical being aerial work platform, raising work platform (EWP), and mobile raising work platform (MAEP). The more struts close, the higher the platform will increase.

Truths About AWP's.

Aerial work platforms come in numerous sizes, and are gasoline-powered or electrical. Smaller variations are great for property owner usage while bigger designs are usually utilized on maintenance and building and construction websites to carry individuals or pallets of products up to different levels. A few of these AWP's consist of electrical generator and air compressor outlets for the use of power tools on the task site.

Safety.

The majority of AWP'S have two control boards, one on the base of the system and one on the platform. In case of power failure, machine operators are geared up with an emergency situation release lever to safely launch the pressure holding up the platform to make a smooth transition back to ground level. The operator on the ground can lower the person and look for medical assistance if the person in the device is injured. This enables two individuals to securely collaborate.

Why Utilize a Scissor Lift?

The advantages of a lift are speed and security. An AWP will permit you to safely develop in the air on a sturdy platform, giving to access to hard-to-reach areas. The little variations permit house owners and their tools to move inside your home and outdoors. By doing this you can access high points such as seamless gutters, high racks in your shop, or devices that is mounted near the ceiling. You can likewise perform window cleaning, roof repair work, and trees cutting. These devices are a momentary, yet versatile way to get your task done while preventing the threats of ladders or having to erect scaffolding. Electrical powered lifts also allow you to work without making use of fuels.

The majority of companies that have a scissor lift rental choice will pick and provide up the unit. If you have a huge job that requires you to utilize a ladder, pick a scissor lift rental company in your location instead to do the job quickly and safely.

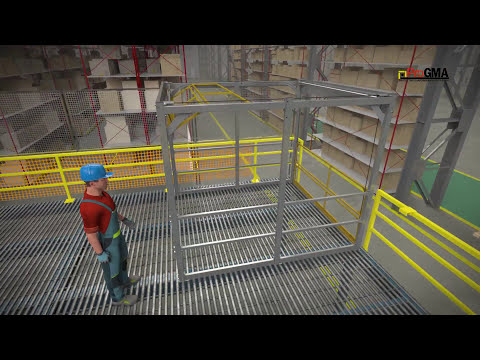

Raised work platforms (EWPs), also known as aerial work platforms (AWPs) are mechanical devices that are used to give access to locations that would formerly be out of reach, mainly on structures or building sites. These typically consist of the work platform itself - typically a small metal base surrounded by a cage or railings and a mechanical 'arm' used to raise the platform.

Other usages consist of usage by fire brigade and emergency services to https://www.rocksolidtraining.com.au access individuals caught inside structures, cliffs or other hazardous heights. Usually they are designed to raise fairly light loads (under a tonne) and so can not be utilized to raise automobiles, generators or pieces of architecture for which a crane would more most likely be used. In some cases nevertheless elevated work platforms can be developed to enable for heavier loads (or 'safe working load', SWL).

Depending on the exact job there are numerous different types of aerial work platform which make use of different mechanisms and fuel sources. The most typical type is the articulated EWP or 'cherry picker' (and also understood as boom raises or hydraulic platforms).

A scissor lift can move only vertically due to various 'unfolding' system of elevation where a criss-cross structure elongates and compresses itself to alter the height. A scissor life can be mechanical, pneumatic or hydraulic. In pneumatic systems lowering requires no energy and just needs that pressure be launched - this implies collapsing quickly is nigh impossible making them slightly safer, though less manoeuvrable, than articulated styles. Their powerfully supported structure also implies that they can bearing greater weight and using a larger platform.

As options there are numerous smaller sized lifts that can function as EWPs making use of mechanical systems such as a rack and pinion or screw threads to extend their height. These tend to have a far shorter reach and bear substantially less weight making them more matched to 'indoor' applications such as reaching leading shelves in storage warehouses or altering light bulbs.